Anyone that has collected, driven or worked on a classic British car built in the 1960’s and 70’s should be familiar with the Borg-Warner 35 transmission (BW-35). It is easily one of the most popular small displacement vehicle transmissions of the era and was installed in well over 100 different models of smaller engined cars. Manufactured at Borg-Warner’s Fairfield, NSW factory, the Borg-Warner 35 is an automatic transmission which features three forward gears and one reverse gear. And, while the gear selector lever varied depending on the various years and car models the transmission was used in, all BW-35’s follow a quadrant with six stations. These are typically labelled as P-R-N-D2-D1-L, or Park, Reverse, Neutral, D2, D1 and Lock.

Table of Contents

Importance Of The Borg Warner 35 Transmission

The importance of the Borg Warner 35 transmission comes from its durability, ease of use and the wide range of British, European, Australian and American cars in which the transmission was used. The BW-35 gearbox would allow for increased fuel economy, especially since drivers could start off in 2nd gear, as well as its ability to start off easily on slippery road surfaces. With its traditional gear quadrant and ability to shift through all three forward gears when placed in the D1 position, it was a welcome alternative to the clunky manual transmissions of the day. New drivers could get in, start the car and drive off without having to fuss with a clutch or finding the right gear and experienced drivers could increase their confidence on snowy or wet roadways.

History Of The Borg Warner 35 Transmission

In 1965, the M-3x series of the Borg-Warner 35 Transmission was updated from the P-R-N-D2-D1-L shift pattern, to the easier, and now common, P-R-N-D-2-1 shift pattern (Park, Reverse, Neutral, Drive, Second, First) and was installed in many British, American and European cars. Also in 1965, the M-36 variant of the BW-35 was introduced. With provisions for an external transmission oil cooler, the BW-35 became much more reliable and suitable for heavier vehicles.

How It Works

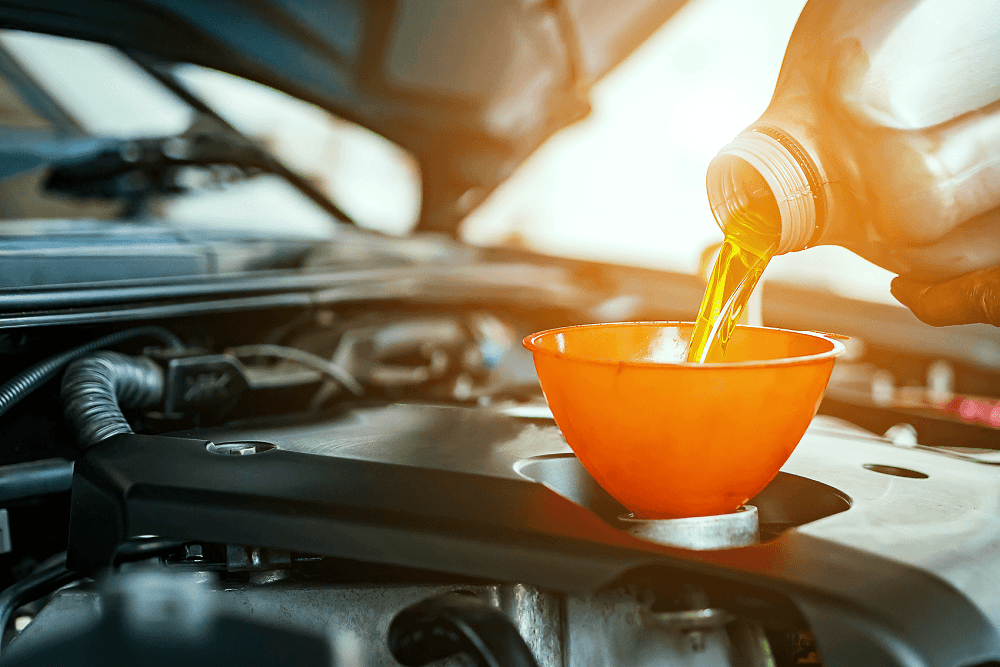

Similar to most automatic gearboxes of the time, the BW-35 was shifted into ‘Drive’ and the vehicle would move off in first gear, changing to second and then to third gear as speed increased. Based on load, the BW-35 would then downshift from 3rd to 2nd and from 2nd to 1st. Kickdown could be felt by the driver, giving them instant feedback and more ‘road feel’. Using a torque converter and an increase or decrease of pressure hydraulic fluid, power could be easily transmitted to the rest of the drivetrain without the need for electronic sensors found in modern transmissions.

Contact Arry The Stag

To learn more about the Borg-Warner 35 transmission and one man’s journey to restore a classic Triumph Stag to its original beauty, contact Arry The Stag today!

If you enjoyed this article, please feel free to share it on your favourite social media sites.

:max_bytes(150000):strip_icc()/GettyImages-522272311-5949bdc15f9b58d58a035319.jpg)